Model:HX-968-corrugated sheet and U panel

Delivery time: 30-35 workdays

Payment: 30% deposit upon order confirmation, 70% balance before shipment.

Warranty Period:2 years

Working voltage: 380v 50hz 3phase(as your need)

WhatsApp: +86 15822768614

E-mail: alan@hx-machinery.com

U panel and corrugated sheet double roll layer forming machine

Our U panel and corrugated sheet double roll layer forming machine is built for U.S. manufacturers who need flexibility and efficiency in metal panel production. This two-in-one machine produces both U panels—widely used in residential and utility buildings in the southern U.S.—and traditional corrugated sheets popular for agricultural and light commercial roofing. The double-layer structure saves floor space and investment cost, while the PLC control system and precision rollers ensure fast, accurate forming with minimal downtime. We provide full technical support and fast delivery across the United States.

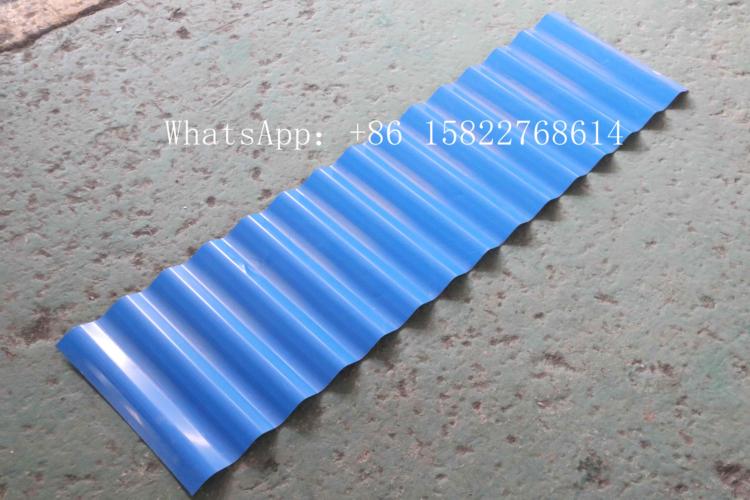

U panel and corrugated sheet double roll layer forming machine photos

U panel and corrugated sheet double roll layer forming machine details

| Number of rows | 13 Rows |

| Speed | 15 m/min |

| Cutting knife material | Cr12Mov |

| Roller diameter | Φ70mm |

| Dimensiones | About 6* 1.4 * 1.6 m |

| Weight | About 4.7 tons |

| Main structure of the machine | 350H beams/450H beams (according to your needs) |

| Transmission mode | Chain drive |

| Chain size | 1.2 inches |

| Side panel | 16 mm |

| Voltage | 380 V 50 Hz three-phase or according to your needs |

| Control system | PLC control |

| Processing precision | Within 1.0 mm |

| Driving mode | Motor driver |

| Power | 5.5kw+4kw |

| PLC language | Chinese + English + According to your local language |

| Rolling stock | Forged #45 steel with chrome plate |

| Length tolerance | ±2 mm |

| Thickness | 0.3-0.8 mm |

| Coil width | 1000mm |

Efficiency & ROI

1.Automatic feeding, cutting, and stacking reduce labor and boost efficiency.

2.Excellent performance at a fair price with fast ROI.

3.We keep wear parts in stock to minimize downtime.

4.Video and online diagnostics for quick problem-solving.

5.Streamlined production ensures timely delivery for your project schedule.

Extra Support & Assistance

1.We can assist you in sourcing raw materials like steel coils for your machine.

2.We update you with shipping dates and help confirm vessel arrangements.

3.We provide machines, matching molds, layout plans, and technical guidance.

4.We serve clients worldwide across various industries, earning strong trust and reputation.

Long-Term Maintenance & Monitoring

1.We regularly check in to monitor performance and offer free maintenance advice.

2.We offer lifetime support even after the warranty ends to keep your machine running smoothly.

3.Each client has a dedicated service file for customized maintenance and upgrade advice.

4.We offer remote or onsite assessments to help improve operational efficiency.