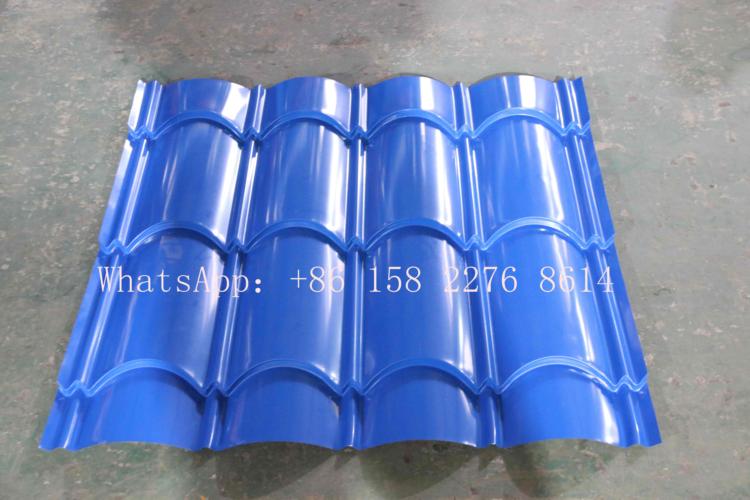

Model:HX-067-tile trapezoidal roof sheet

Delivery time: 20-30 workdays

Payment: 30% deposit upon order confirmation, 70% balance before shipment.

Warranty Period:2 years

Working voltage: 380v 50hz 3phase(as your need)

WhatsApp: +86 15822768614

E-mail: alan@hx-machinery.com

double layer trapezoidal and tile roofing machine

With 28 years of experience in the metal forming industry, we are a quality-focused Chinese manufacturer dedicated to designing and producing reliable machinery for roofing applications. Our commitment to excellence is reflected in every step of our production process—from material selection to final testing. We understand the needs of the Sri Lankan construction market and strive to provide equipment that is both durable and energy-efficient. Our roofing machine is built to handle long-term, high-volume operation while maintaining precision and consistency. Whether for industrial or commercial projects, we deliver tailored solutions that help Sri Lankan clients succeed in a competitive market.

double layer trapezoidal and tile roofing machine photos

double layer trapezoidal and tile roofing machine technical parameters and details

| Rows | 13rows+18rows |

| Speed | 15m/min |

| Dimensions | about 8.5*1.4*1.7m |

| Main structure of the machine | 350H beams |

| Side panel of machine | 16mm |

| Control system | PLC control |

| Power | 5.5kw+4kw |

| Length Tolerance | ±2mm |

| Thickness | 0.3-0.8mm |

| Coil Width | 914mm (as your need) |

Advantages: Why choose us?

1. Strict Quality Control:Each machine undergoes multiple inspections before delivery, ensuring dependable quality and peace of mind.

2. Energy-Efficient Design:With energy-saving motors and frequency control technology, our machines help reduce electricity costs.

FAQ: Your questions, our answers

1.How Many People Are Needed to Operate the Machine?

Thanks to our intelligent PLC control system, the machine can be efficiently and safely operated by just one skilled person.

2.Do You Accept OEM Orders?

Absolutely, we support OEM customization. Our skilled engineering team can design and manufacture machines according to your specifications or technical drawings, using premium-brand components to guarantee high quality.

After-sales service

1. Onsite Repair Service:When necessary, we can dispatch experienced engineers to your facility for onsite service, subject to local visa and travel policies.

2. Customer File Management:Each customer has a dedicated service file to track machine usage and provide tailored maintenance and upgrade advice.

3. Affordable Spare Parts:We supply original spare parts at competitive prices with fast delivery, ensuring reliable performance of your production line.