Model:HX-902-TR4

Delivery time: 20-30 workdays

Payment: 30% deposit upon order confirmation, 70% balance before shipment.

Warranty Period:2 years

Working voltage: 380v 50hz 3phase(as your need)

WhatsApp: +86 15822768614

E-mail: alan@hx-machinery.com

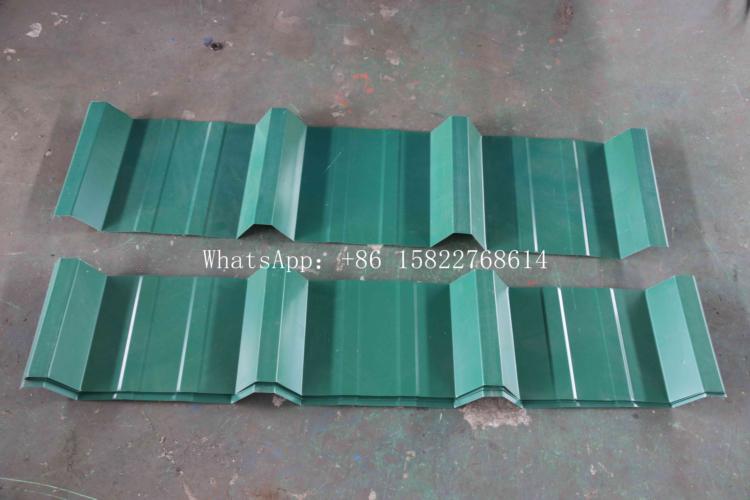

TR4 roof sheet making machine

The TR4 roof sheet making machine is engineered to produce high-quality trapezoidal roofing sheets with precise profile definition and excellent surface finish. Featuring a reinforced structure, hardened rollers, and an advanced control system, this machine ensures stable performance, high production speed, and long-lasting durability—ideal for both industrial and commercial roofing projects.

TR4 roof sheet making machine photos

TR4 roof sheet making machine details

| Number of rows | 20 Rows |

| Speed | 15m/min |

| Cutting knife material | Cr12Mov |

| Roller diameter | Φ70mm |

| Dimensiones | About 9.7 * 1.4 * 1.6 m |

| Weight | About 6 tons |

| Main structure of the machine | 350H beams/450H beams (according to your needs) |

| Transmission mode | Chain drive |

| Chain size | 1.2 inches |

| Side panel | 16 mm |

| Voltage | 380 V 50 Hz three-phase or according to your needs |

| Control system | PLC control |

| Processing precision | Within 1.0 mm |

| Driving mode | Motor driver |

| Power | 5.5kw+4kw |

| PLC language | Chinese + English + According to your local language |

| Rolling stock | Forged #45 steel with chrome plate |

| Length tolerance | ±2 mm |

| Thickness | 0.3-0.8 mm |

| Coil width | 1220mm |

Performance & Quality Advantages

1.Built with advanced technology and premium components, ensuring efficient, consistent operation.

2.Forming accuracy within ±2mm for consistent quality and a professional finish.

3.Made with high-strength alloy steel and wear-resistant materials for long service life.

4.Energy-saving motors and frequency control reduce electricity costs.

5.Environmentally friendly paints and materials support green production.

Company & Service Overview

1.We are a professional roll forming machine manufacturer from Tianjin, China, founded in 2013, exporting worldwide.

2.We welcome OEM. Our engineers develop equipment based on your drawings and requirements with top-tier components.

3.We are a direct manufacturer with 28 years of experience in roll forming machinery.

Technical Support & Warranty

1.We offer onsite or remote training to ensure your operators can safely and efficiently run the machine from day one.

2.Our team is available 24/7 via phone, WhatsApp, or video to resolve issues promptly.

3.We guide you remotely to locate and fix problems—minimizing downtime and cost.

4.Full 2-year warranty with free replacement of defective parts (excluding man-made damage).