Model:HX-917-1000 trapezoidal sheet

Delivery time: 20-30 workdays

Payment: 30% deposit upon order confirmation, 70% balance before shipment.

Warranty Period:2 years

Working voltage: 380v 50hz 3phase(as your need)

WhatsApp: +86 15822768614

E-mail: alan@hx-machinery.com

1000 trapezoidal metal roof making machine

The 1000 trapezoidal metal roof making machine is engineered to produce high-quality trapezoidal roofing sheets with an effective width of 1000 mm. Featuring a heavy-duty steel structure, precision-machined rollers, and an advanced PLC control system, it ensures consistent forming accuracy, smooth surface finish, and reliable long-term operation. This machine is ideal for metal roof manufacturers focused on durability, efficiency, and production flexibility.

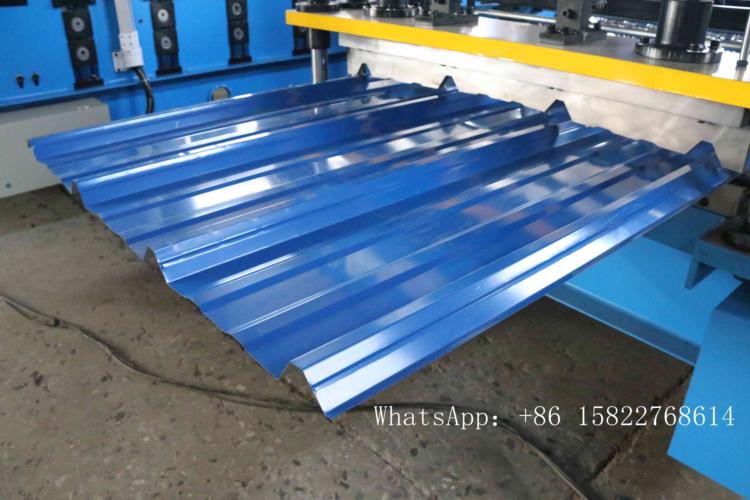

1000 trapezoidal metal roof making machine photos

1000 trapezoidal metal roof making machine details

| Number of rows | 14 Rows |

| Speed | 15m/min |

| Cutting knife material | Cr12Mov |

| Roller diameter | Φ70mm |

| Dimensiones | About 6.5 * 1.4 * 1.6 m |

| Weight | About 5 tons |

| Main structure of the machine | 350H beams/450H beams (according to your needs) |

| Transmission mode | Chain drive |

| Chain size | 1.2 inches |

| Side panel | 16 mm |

| Voltage | 380 V 50 Hz three-phase or according to your needs |

| Control system | PLC control |

| Processing precision | Within 1.0 mm |

| Driving mode | Motor driver |

| Power | 5.5kw+4kw |

| PLC language | Chinese + English + According to your local language |

| Rolling stock | Forged #45 steel with chrome plate |

| Length tolerance | ±2 mm |

| Thickness | 0.3-0.8 mm |

| Coil width | 1200/1220mm |

Performance & Quality Advantages

1.Built with advanced technology and premium components, ensuring efficient, consistent operation.

2.Forming accuracy within ±2mm for consistent quality and a professional finish.

3.Made with high-strength alloy steel and wear-resistant materials for long service life.

4.Energy-saving motors and frequency control reduce electricity costs.

5.Environmentally friendly paints and materials support green production.

Company & Service Overview

1.We are a professional roll forming machine manufacturer from Tianjin, China, founded in 2013, exporting worldwide.

2.We welcome OEM. Our engineers develop equipment based on your drawings and requirements with top-tier components.

3.We are a direct manufacturer with 28 years of experience in roll forming machinery.

Spare Parts & Optimization

1.Original parts with fast delivery and competitive prices ensure reliable operation.

2.We help optimize your production flow based on your layout and needs.

3.We analyze power usage and suggest ways to reduce consumption and costs.

4.Engineers can be dispatched for onsite service as local travel policies allow.